Concrete stands as the backbone of modern architecture, yet its raw strength is not enough without the secret ingredient – reinforcing steel. Understanding this inseparable duo is crucial for any sustainable construction.

Introduction

Imagine a world where our structures could withstand centuries of stress without bending. This dream is made possible through an underappreciated collaboration: that of concrete and reinforcing steel. Concrete, when reinforced with a metallic skeleton, confronts challenges that would shatter any other material. Let’s explore why reinforcing steel is the key ingredient for long-lasting constructions.

Roles of Concrete and Reinforcing Steel

Every material in a construction plays a part, like partners in a complex dance. Renowned for its ability to endure without yielding to pressure, concrete is the obvious choice for solid foundations and imposing columns. Reinforcing steel, on the other hand, operates in the shadows, stepping in when tension arises.

Fundamentals of Concrete and Internal Forces

To fully grasp why reinforcing steel is essential to concrete, a basic understanding of material mechanics is necessary. This allows us to examine how materials react under various strains.

Materials are subjected to three main types of stress:

- Compression: When the material is pressed or crushed.

- Tension: The opposite force, when a material is stretched or pulled.

- Shear: Here, the material is subjected to a force pushing in two opposite directions, causing deformation or slippage.

Concrete stands like a fortress against compression, capable of supporting enormous loads without surrendering. However, when stretched or bent – forces that put it under tension – its resistance is far less impressive. Tension is the force that tends to pull on concrete, stretching it and potentially causing cracks. Envision suspending a concrete slab by its ends; under its own weight, it might start to sag and eventually break.

This inherent weakness in tension limits the use of concrete in structures where opposing forces may be exerted, risking fractures. To counter this, integrating a complementary material that excels under tension is indispensable; enter reinforcing steel.

Practical Experience: Concrete Under Stress

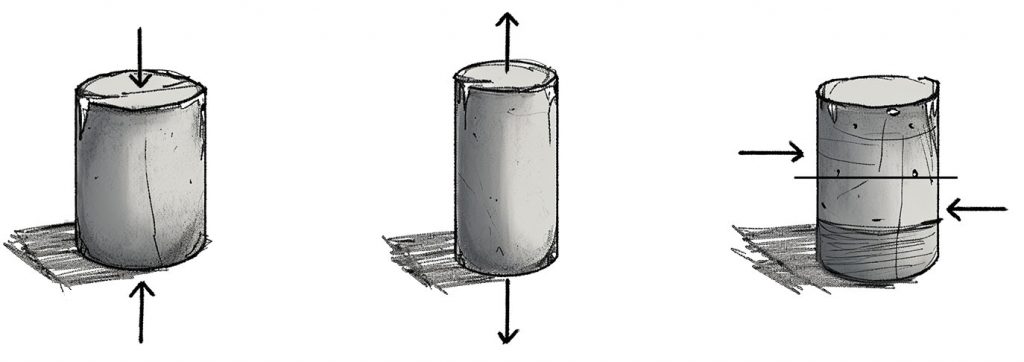

To better illustrate the difference in resistance between compression and tension in concrete, a good practical demonstration is invaluable. Let’s take two concrete cylinders from the same mix for a test.

Compression Test

Imagine we apply a force from the top down on the first cylinder. Under compression, concrete shows all its solidity. This cylinder can support a considerable load before giving way. However, for concrete, the maximum pressure it can withstand varies based on its mix; concrete with a lot of water, for example, will be less resistant.

Tension Test

Now, take the second cylinder and suspend it. We begin adding weight until the concrete can no longer hold. You might be surprised to see that it doesn’t take a lot of weight for the concrete cylinder to crack or even break. The force it can bear under tension is significantly less than under compression, often less than 10%.

Conclusion: Although concrete can easily support heavy loads when crushed, it is much less effective when stretched or pulled. This is crucial information because in most structural applications, elements must resist both compression and tension.

The Reality of Concrete Structures

The real world of concrete construction isn’t limited to laboratory tests. The structures we design and use every day are constantly subject to various forces and must be designed to withstand them. Rarely is a concrete structure solicited solely in compression. In practice, it often faces a mix of stresses, including compression, tension, and shear.

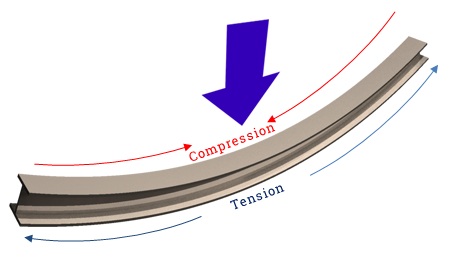

Consider a classic beam made entirely of concrete. When we apply a load to the beam, like the weight of a bridge or the floor of a building, the concrete inside this beam starts working. The internal forces manifest differently across the beam:

- The top of the beam undergoes compression.

- The bottom of the beam is under tension.

Due to its weakness in tension, it is usually the lower part of the concrete beam that will show cracks, and, with the continuous increase in load, that’s where breaking will occur. Concrete alone, without reinforcement, can thus break abruptly and prematurely.

Crucial Role of Reinforcing Steel

Reinforcing steel is the solution we use to counterbalance concrete’s weakness in tension. Adding steel creates a composite material where concrete continues to excel in compression, and steel takes over tension forces. It’s a perfect collaboration between two materials that compensate for each other’s weaknesses.

Deformed steel rebar, because of its ribs, is the most commonly used type of reinforcing steel. Indeed, these ribs increase adherence with concrete, thus creating a strong bond between the two materials. A beam reinforced with steel bars is far more resistant to loads and especially shows a behavior under pressure very different from concrete alone.

Advantages of Reinforcing Steel in Construction

- Economical: Compared to other types of steel, it offers a cost-effective solution for reinforcing concrete.

- Strength: Its ribbed structure firmly latches onto concrete, giving it an increased capacity to hold under tension.

- Flexibility: Available in different sizes and shapes, it can be shaped to fit various structural applications.

The Alternative of Prestressed Concrete

Despite its many advantages, reinforcing bars are not without disadvantages. As a form of passive reinforcement, it only starts working, that is, resisting tension, when the concrete begins to crack and stretch, which can lead to visible deformation and cracks.

For cases where it is particularly important to avoid cracks or excessive deformation caused by passive reinforcement, engineers often turn towards active reinforcement, known as prestressed concrete.

Prestressed Concrete

Prestressing involves applying a force on the reinforcing steel before the concrete is put under load in the finished structure. There are two main methods:

- Pre-tension: Steel cables are stretched before the concrete is poured. Once the concrete has hardened, this tension remains and transfers a compressive force to the concrete, thanks to friction with the steel.

- Post-tension: Here, the tension is applied after the concrete has hardened, using cables that can be adjusted to exert an optimal compressive force.

Both methods contribute to a distribution of forces that improves the concrete’s resistance to external loads without prematurely showing cracks.

Conclusion

The combination of concrete and reinforcing steel creates robust and resilient structures. Concrete, weak in tension, gains capacity thanks to reinforcing steel, allowing structures to resist significant dynamic forces. This synergy, essential for the safety and durability of edifices, relies on complex engineering principles, requiring meticulous attention for each project.